Tank Vehicles

8.1 – Inspecting Tank Vehicles

Tank vehicles have special items that you need to check. Tank vehicles come in many types and sizes. You need to check the vehicle’s operator manual to make sure you know how to inspect your tank vehicle.

8.1.1 – Leaks

On all tank vehicles, the most important item to check for is leaks. Check under and around the vehicle for signs of any leaking. Don’t carry liquids or gases in a leaking tank. To do so is a crime. You will be cited and prevented from driving further. You may also be liable for the clean up of any spill. In general, check the following:

- Check the tank’s body or shell for dents or leaks.

- Check the intake, discharge, and cut-off valves. Make sure the valves are in the correct position before loading, unloading, or moving the vehicle.

- Check pipes, connections, and hoses for leaks, especially around joints.

- Check manhole covers and vents. Make sure the covers have gaskets and they close correctly. Keep the vents clear so they work correctly.

8.1.2 – Check Special Purpose Equipment

If your vehicle has any of the following equipment, make sure it works:

- Vapor recovery kits.

- Grounding and bonding cables.

- Emergency shut-off systems.

- Built in fire extinguisher.

Never drive a tank vehicle with open valves or manhole covers.

8.1.3 – Special Equipment

Check the emergency equipment required for your vehicle. Find out what equipment you’re required to carry and make sure you have it (and it works).

8.2 – Driving Tank Vehicles

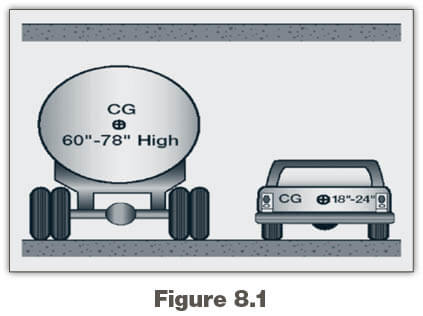

Hauling liquids in tanks requires special skills because of the high center of gravity and liquid movement. See Figure 8.1.

8.2.1 – High Center of Gravity

High center of gravity means that much of the load’s weight is carried high up off the road. This makes the vehicle top-heavy and easy to roll over. Liquid tankers are especially easy to roll over. Tests have shown that tankers can turn over at the speed limits posted for curves. Take highway curves and on ramp/off ramp curves well below the posted speeds.

8.2.2 – Danger of Surge

Liquid surge results from movement of the liquid in partially filled tanks. This movement can have bad effects on handling. For example, when coming to a stop, the liquid will surge back and forth. When the wave hits the end of the tank, it tends to push the truck in the direction the wave is moving. If the truck is on a slippery surface such as ice, the wave can shove a stopped truck out into an intersection. The driver of a liquid tanker must be very familiar with the handling of the vehicle.

8.2.3 – Bulkheads

Some liquid tanks are divided into several smaller tanks by bulkheads. When loading and unloading the smaller tanks, the driver must pay attention to weight distribution. Don’t put too much weight on the front or rear of the vehicle.

8.2.4 – Baffled Tanks

Baffled liquid tanks have bulkheads in them with holes that let the liquid flow through. The baffles help to control the forward and backward liquid surge. Side-to-side surge can still occur. This can cause a roll over.

8.2.5 – Un-baffled Tanks

Un-baffled liquid tankers (sometimes called “smooth bore” tanks) have nothing inside to slow down the flow of the liquid. Therefore, forward-and-back surge is very strong. Un-baffled tanks are usually those that transport food products (milk, for example). (Sanitation regulations forbid the use of baffles because of the difficulty in cleaning the inside of the tank.) Be extremely cautious (slow and careful) in driving smooth bore tanks, especially when starting and stopping.

8.2.6 – Outage

Never load a cargo tank totally full. Liquids expand as they warm and you must leave room for the expanding liquid. This is called “outage.” Since different liquids expand by different amounts, they require different amounts of outage. You must know the outage requirement when hauling liquids in bulk.

8.2.7 – How Much to Load?

A full tank of dense liquid (such as some acids) may exceed legal weight limits. For that reason, you may often only partially fill tanks with heavy liquids. The amount of liquid to load into a tank depends on:

- The amount the liquid will expand in transit.

- The weight of the liquid.

- Legal weight limits.

8.3 – Safe Driving Rules

In order to drive tank vehicles safely, you must remember to follow all the safe driving rules. A few of these rules are:

8.3.1 – Drive Smoothly

Because of the high center of gravity and the surge of the liquid, you must start, slow down, and stop very smoothly. Also, make smooth turns and lane changes.

8.3.2 – Controlling Surge

Keep a steady pressure on the brakes. Do not release too soon when coming to a stop.

Brake far in advance of a stop and increase your following distance.

If you must make a quick stop to avoid a crash, use controlled or stab braking. If you do not remember how to stop using these methods, review subsection 2.17.2. Also, remember that if you steer quickly while braking, your vehicle may roll over.

8.3.3 – Curves

Slow down before curves, then accelerate slightly through the curve. The posted speed for a curve may be too fast for a tank vehicle.

8.3.4 – Stopping Distance

Keep in mind how much space you need to stop your vehicle. Remember that wet roads double the normal stopping distance. Empty tank vehicles may take longer to stop than full ones.

8.3.5 – Skids

Don’t over steer, over accelerate, or over brake. If you do, your vehicle may skid. On tank trailers, if your drive wheels or trailer wheels begin to skid, your vehicle may jackknife. When any vehicle starts to skid, you must take action to restore traction to the wheels.

Test Your Knowledge

- How are bulkheads different than baffles?

- Should a tank vehicle take curves, on ramps, or off ramps at the posted speed limits?

- How are smooth bore tankers different to drive than those with baffles?

- What three things determine how much liquid you can load?

- What is outage?

- How can you help control surge?

- What two reasons make special care necessary when driving tank vehicles?

These questions may be on the test. If you can’t answer them all, re-read Section 8.